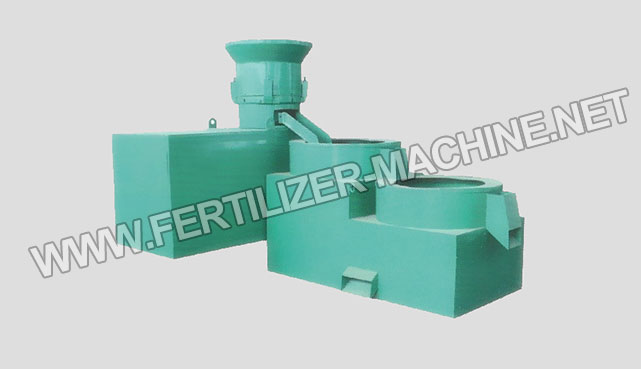

Introduction to Disc Fertilizer Granulating Machine

Disc fertilizer pelletizer is an important part of organic fertilizer production. Disc granulator is widely used for producing round granules of organic fertilizer and compound fertilizer, which are convenient for transportation and storage. Having the features of uniform granules, high granulation rate, smooth running, and long service life, pan granulator is an ideal pellet machine for your fertilizer production. Various models of disc fertilizer pelletizer are manufactured in our factory. They vary with inner diameter, side height, and rotating speed. Customers can choose whichever model of fertilizer granulator in the light of their production capacity.

Features of High-output Disc Fertilizer Granulator

1. Adopt whole arc disc angle, the granulation rate can reach above 93%.

2. Having three discharge ports makes it convenient for intermittent production, greatly reducing the labor intensity and improving labor efficiency.

3. Motor and reducer adopts flexible belt drive, ensuring a smooth start and increasing the service life of equipment.

4. Gears adopt high-frequency quenching, which doubles the service life.

5. The disc is lined with high strength glass fiber reinforced plastics, anti-corrosion and durable in use.

6. Disc bottom uses multiple radiation steel plates to reinforce, sturdy and durable, never deform.

7. Sturdy base design, no need for foundation bolt, smooth running.

8. Automatic material clearing plate above the disc removes the sticking materials, improving service life of equipment and saving labor.

Wide Applications of Pan Fertilizer Pelletizer

1. Disc granulator is suitable for the granulation of organic fertilizer, inorganic compound fertilizer, organic compound fertilizer, bio-organic fertilizer, etc.

2. Disc fertilizer pelletizer has wide adaptability to raw materials.

– Nitrogen source: urea, ammonium chloride, ammonium sulfate, ammonium carbonate, etc.

– Phosphorus source: superphosphate, coarse whiting, monoammonium phosphate, diammonium phosphate, calcium magnesium phosphate, etc.

– Potassium source: potassium chloride, potassium sulfate, etc.

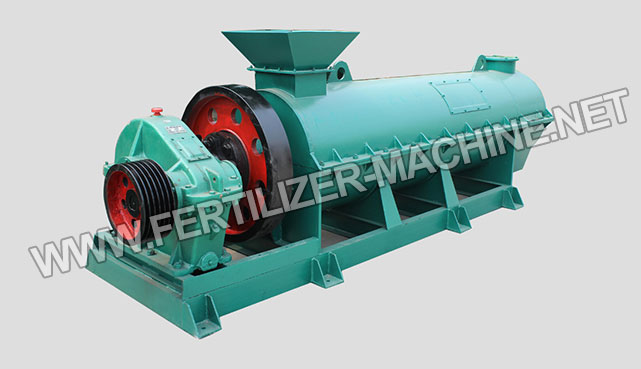

How Does the Disc Fertilizer Pellet Machine Work?

The whole disc of the granulation equipment is fixed on the main shaft of regulating plate. The motor drives the belt pulley, triangle belt, speed reducer and small gear, which drives the large gear under the granulating disc, making the disc work. After the materials enter into the disc, by the continuous rotating of disc and spraying device, materials bond together evenly, forming round granules. Large granules float to the top and discharge through the outlet. Small granules continue to bond with new materials until discharged.

Technical Data of Disc Fertilizer Pellet Machine

| Model | Inner Diameter (mm) |

Side Height (mm) |

Volume (m³) |

Rotating Speed (r/min) |

Power (kw) |

Output

(t/h)

|

| ALCZL10 | 1000 | 250 | 0.4 | 24 | 2.2 | 0.3-0.5 |

| ALCZL15 | 1500 | 300 | 1.1 | 22 | 5.5 | 0.5-0.8 |

| ALCZL20 | 2000 | 350 | 1.8 | 18 | 7.5 | 0.8-1.2 |

| ALCZL25 | 2500 | 350 | 2.5 | 18 | 7.5 | 1.0-1.5 |

| ALCZL28 | 2800 | 400 | 3.3 | 18 | 11 | 1.0-2.5 |

| ALCZL30 | 3000 | 450 | 3.9 | 16 | 11 | 2.0-3.0 |

| ALCZL32 | 3200 | 500 | 4.3 | 13.6 | 15 | 2.0-3.5 |

| ALCZL36 | 3600 | 550 | 5.5 | 11.3 | 18.5 | 3.0-5.0 |

| ALCZL45 | 4500 | 600 | 6.5 | 8 | 22 | 4.0-6.0 |