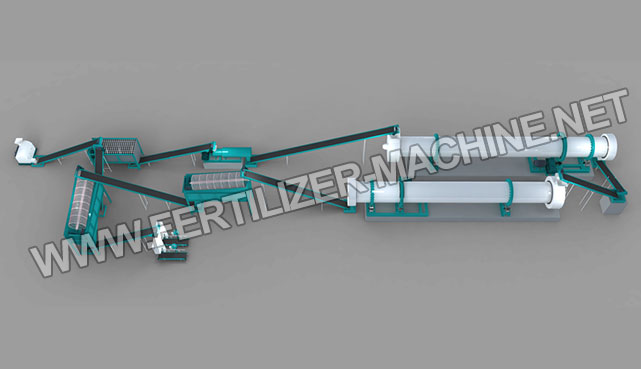

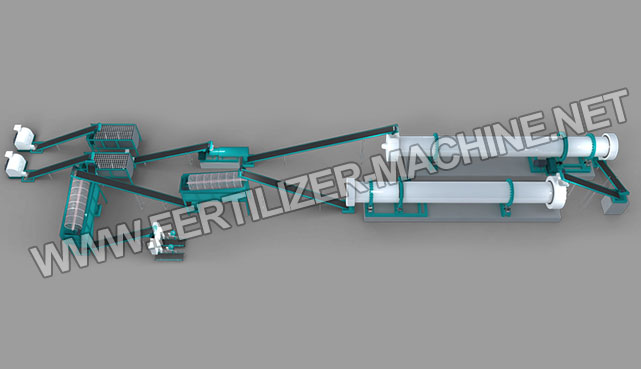

Introduction of 30,000 Ton/Year Compound Fertilizer Production Line:

The whole set of production line, which is equipped with advanced and high-efficiency machines, can achieve 30,000 tons compound fertilizer production annually. According to the capacity, our compound fertilizer equipment is divided into 20,000 tons, 30,000 tons, and 50,000 tons. Customers can choose whichever production line at will. The compound fertilizer granulation production line is with lower investment, and better economic returns. The Complete equipment are distributed compactly, reasonably, and scientific. All machines, such as fertilizer mixer, fertilizer granulator, fertilizer coating machine etc. run smoothly, with features of more energy-saving, lower maintenance cost, and easier operation.

Working Process of Medium Scale Compound Fertilizer Production Plant:

The technical process of compound fertilizer production line generally goes like this: materials proportioning, evenly mixing, particles granulation, rotary drum drying, cooling, compound fertilizer coating, packaging.

1. Materials proportion system: in the light of market demand, and local soil-determining findings, raw materials, such as urea, ammonium nitrate, and potassium chloride etc. are dispensed according to a given proportion. N, P, K, additives, and trace elements are introduced into proportioner through the belt weigher in fixed proportion. According to formula ratio, all raw materials flow to the belt uniformly, which can be called Premix. It ensures accurate formula, and achieves an efficiently continuous processing.

2. Raw materials mixing: the selection of horizontal mixer which is an essential component in fertilizer production, helps thoroughly mix raw materials again, higher granules yield. We manufacture both single-shaft horizontal mixer and double-shaft horizontal mixer so that our clients can choose a more suitable one according to their productivity and preference.

3. Fertilizer granulating: the core part in compound fertilizer production. It is essential to select fertilizer granulator. Customers can choose disc granulator, rotary drum granulator, roller extrusion granulator or new type fertilizer granulator putting into production. Here, we choose rotary drum granulator. After mixing evenly, with the power of belt conveyor, materials are transformed to the disc granulator to granulate uniformly sized particles.

4. Fertilizer drying and cooling system: Our high-output rotary drum drying machineis a drying equipment to reduce the moisture content of the end products. After drying, the moisture content of compound fertilizer will be reduced from 20%-30% to 2%-5%. After drying, all materials need to be send into cooler. The rotary drum cooling machine is connected with the rotary dryer with belt conveyor, to remove the dust and clean the exhaust together, which can improve the cooling efficiency and the rate of thermal energy utilization, reduce labor intensity, and further remove moisture of the fertilizer.

5. Fertilizer screening: After cooling, there is still powdered materials in the end products. All fines and large particles can be screened out using our rotary drum screening machine. Then, fines being transported by belt conveyor are back to horizontal mixer for remixing and re-granulating with raw materials. While large particles needs to be crushed in chain crusher before re-granulation. Quasi-finished products are conveyed into compound fertilizer coating machine. In this way, a complete production cycle is formed.

6. Compound fertilizer coating: the rotary drum coating machine manufacture by us is driven by main motor, belt, pulley and drive shaft. It is mainly used to coat a uniform layer of protective film in the surface of compound fertilizer, which effectively restrains the salt bridge and absorption of organic fertilizer, and makes the particles more smooth. After coating, there is coming the final process of the whole production–packaging.

7. Fertilizer packaging system: automatic quantitative packaging machine is adopted in this process. It consists of automatic weighing and packing machine, transport system, sealing machine and feeding machine. Feed bin also can be equipped according to customers’ demands. It can realize the quantitative package of the supplies in bulk, such as organic fertilizer and compound fertilizer, and has already widely used in the food processing factory, industrial production line, etc.

Advantage of High-output Compound Fertilizer Production Line

1.Wide raw materials range. Our compound fertilizer production line applies to granulation of various kinds of raw materials, such as fertilizer, pharmaceuticals, chemicals, and feed etc.

2. High compound fertilizer yield. This production line can produce different concentrations of compound fertilizer according to the ratio of raw materials.

3. Low-cost. You know all fertilizer machines are manufactured by our own. There is no middleman, no distributors, which exactly means we are directly seller. We manufacture, and we do foreign-trade, maximizing the benefits of our customers with low investment. Besides, it is possible for our clients to contact with us in time if there is some technical problems or assembling doubts.

4. Well physical character. Compound fertilizer produced by our production line is with small moisture absorption, and easy-storage, especially convenient for mechanized application.

5. The whole set of fertilizer production line accumulates years of technical experience and productivity. It is a high-efficiency and low-power fertilizer production line innovated, reformed, and designed times, which has successfully resolved problems of low efficiency and high costs at home and abroad.

Technical Data of 30,000 T/Y Compound Fertilizer Production Line

|

Product Item

|

Model

|

Motor Power

(kw) |

Prod Capacity

(t/h) |

Weight

(t)

|

Inclination

|

Dimension

L x W x H(mm)

|

|

Disc Mixer

|

ALCPJ1800

|

7.5

|

4-6

|

1400

|

1900*1812*1368

|

|

|

Rotary Drum Granulator

|

ALCZG1.6×6

|

11

|

5-8

|

12.0

|

2–2.5

|

700*320*310

|

|

Rotary Drum Dryer

|

ALCZG18150

|

18.5

|

7-10

|

2-5

|

Shell L x inner dia:

15000*1800 |

|

|

Rotary Drum Cooler

|

ALCLQ15150

|

15

|

2-5

|

Shell L x inner dia:

15000*1500 |

||

|

Rotary Drum Screening Machine

|

ALCGS1.5×5.0

|

5.5

|

5-10

|

3.8

|

2-2.5

|

Shell L x dia:

5000*1500 |

|

Rotary Drum Coating Machine

|

ALCBM1200×4000

|

5.5

|

~5

|

3

|

Shell L x inner dia:

4000*1200 |

|

|

Chain Crusher

|

ALCLP800

|

15

|