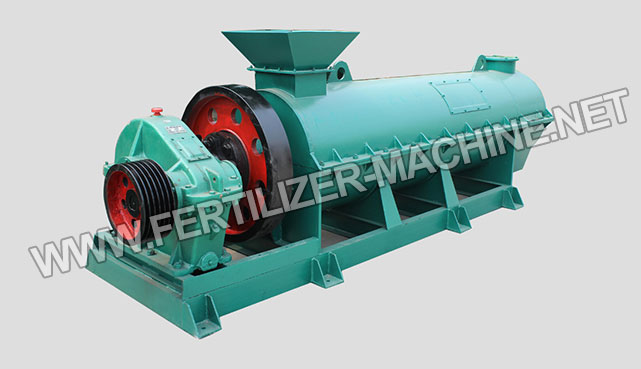

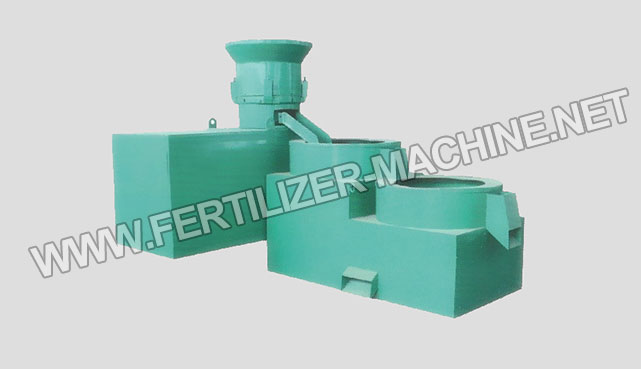

New Type Organic Fertilizer Dedicated Granulator Introduction:

New Type Organic Fertilizer Granulator is manufactured by the latest technology in the field of organic fertilizer production. It is used to granulate all kinds of organic raw materials after fermentation process. Different from the traditional ways of making

organic fertilizer, raw materials don’t need to be dried or crushed, which makes the whole producing process more efficient and energy-saving. The final organic fertilizer granules are spherical and highly qualified, which makes the one-time production of uniformly spherical fertilizer granules come true. Its production rate can reach as high as 1-2t/h,so it is considered as the most effective and eco-friendly way of organic fertilizer production at present.

New Type Organic Fertilizer Dedicated Granulator Features:

1. Both the concentration of organic raw materials and the granulation rate are high, so it can produce 100% pure organic fertilizer granules, which meets the needs of customers directly.

2. The final granules are spherical and uniformly shaped, which prolongs the quality of the organic fertilizer granules.

3. This machine produces particles with high hardness, which can be screened immediately after the granulation process. Thus, it can save the energy that is wasted in the fertilizer drying process.

4. Organic raw materials don’t need to be dried or crushed, which makes the producing process more effective and economic.

5. The size of the organic fertilizer granules can be changeable, if you change the quantity of the mixed raw materials and the revolving speed of the principle axis. Customers can adjust it properly to produce whatever they want.

6. Take advantages of the features that organic fertilizer particles can be inlaid with each other under some conditions. So no binders need to be added during the granulation process.

7. After fermentation, raw materials needn’t to be dried. And the moisture of the raw materials can be controlled between 20-40%.

8. This machine has a steady performance, and is made of anti-corrosive and wear-resistant materials, which prolongs a long

service life of the machine.

New Type Organic Fertilizer Dedicated Granulator Working Principles:

Forced by the high revolving speed and the aerodynamics it brings, raw materials can be mixed, granulated, spherified and concentrated in this machine at a time. Thus, a complete granulation process is perfectly accomplished. The granules are spherical, and their sizes can be changed as long as you change the quantity of the mixed organic raw materials supplement or the revolving speed of the principle axis. Generally speaking, the larger quantity of the mixed raw materials or the higher revolving speed of the principle axis, the smaller sizes of the fertilizer granules; and vice versa.

New Type Organic Fertilizer Dedicated Granulator Applications:

It is applied to granulate all kinds of organic raw materials, which turns the waste into treasures and follows the trends of the organic fertilizer development. The quality of the fertilizer granules can be ensured at the same time, so this fertilizer machine is featured with low energy consumption, low production expenses and high production quantity, considered as best organic fertilizer granulator machine. It is the most widely used equipment in small scale organic fertilizer plant, and 50,000t/y production line!

Raw Materials for Organic Fertilizer Granulation:

The raw materials of organic fertilizer production are varied.

1. Agricultural Waste:

straws, cottonseed meals, mushroom residues, bio-gas residues etc.

2. Industrial Waste:

vinegar residues, sugar residues, lees etc.

3. Animal Manure or Sludge:

chicken manure, cow manure, horse manure, drainage sludge, river sludge etc.

4. Household Garbage: kitchen waste, food waste, restaurant garbage etc.

Technical Data of New Type Organic Fertilizer Dedicated Granulator

|

Model

|

Production Capacity(t/h)

|

Power (kw)

|

|

ALCYSL-40

|

1-1.5

|

22

|

|

ALCYSL-60

|

1.5-2

|

30

|

|

ALCYSL-80

|

2-4

|

45

|

|

ALCYSL-100

|

4-6

|

55

|

|

ALCYSL-120

|

6-8

|

75

|