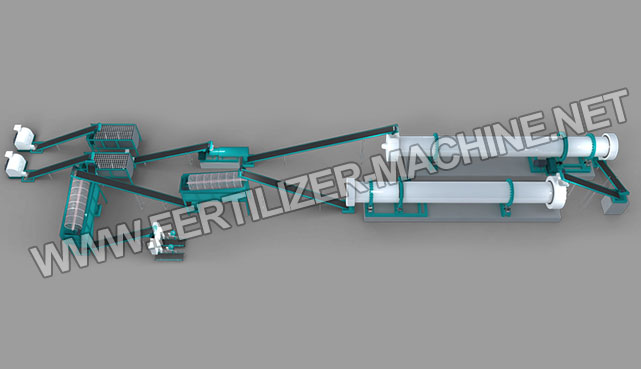

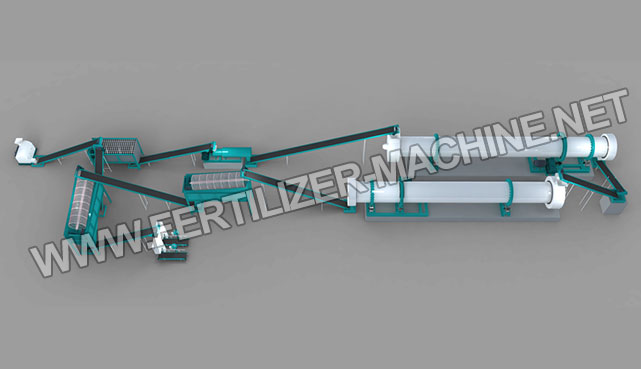

Introduction of Complete Set of Bio-organic Fertilizer Production Line

50,000 tons/year new type organic fertilizer production line is used to make organic fertilizer with different organic materials which includes agricultural waste, animal manure, sludge, and urban waste etc. The whole fertilizer production line is not only process different fermented organic materials into fertilizer, but can do great benefit to the community and environment. This new type complete organic fertilizer production line consists of compost windrow turner, fertilizer mixer, crusher, fertilizer granulator, dryer, cooler and fertilizer packager and so on. With features of stable performance, high efficiency, convenient maintenance, and long service life, it enjoys great popularity in fertilizer industry, especially in Asia and Africa.

Features of New Type Organic Fertilizer Production Line

1. This line is not only suitable for organic fertilizer, but also bio-organic fertilizer if function bacteria is added, organic and inorganic fertilizer if nitrogen, phosphorus and potassium is added.

2. The diameter of fertilizer can be adjusted according to customer’s need. There are various kinds of fertilizer granulators being provided in our factory, such as new type organic fertilizer granulator, disc granulator, flat die fertilizer granulator, and bio-organic fertilizer spherical granules granulator etc. Customers can produce different shapes of granules using our fertilizer pellet mills.

3. Widely application. It can process different raw materials, such as animal manure waste, agricultural waste, ferment materials, chemical products. All those organic materials can be fermented and granulated into large-output organic fertilizers.

4. Highly automatic and high precision. The batching system and packing machine are controlled by computer to realize automation.

5. High quality, stable performance, easy to operate, highly automatic, long service life. We has taken full consideration of user experience when designing and manufacturing fertilizer machines.

50,000 tones/year New Type Fertilizer Production Line

50,000 tons/year new type fertilizer production line is an ideal fertilizer plant in the fertilizer industry. The main production process is crushing the fermentation rotten materials of moisture about 30%-35%, then mixing, granulating, drying, cooling, screening, and the final product is achieved. The main equipment of this 50,000 tons/year new type fertilizer production line is as follows:

Working Process of New Type Organic Fertilizer Production Line

1. Fermentation: Organic materials fermentation process is important in the production. The temperature of the materials should be controlled carefully to prevent the temperature being too high to inhibit the activity of microbes and enzymes. Self-propelled compost turner and hydraulic compost turner are widely used to turn and mix the compost and accelerate the fermentation.

2. Crushing: After the fermentation process, the compost lump materials should be ground by crushing machine. Customers can choose semi-wet materials crusher, chain crusher or cage crusher at will. We recommend semi-wet materials crusher here.

3. Mixing: Use horizontal mixer or vertical mixer in this process to mix the materials and additives evenly. The additives can be added according to the nutrition requirements of different crops.

4. Drying: Before granulating, if the moisture of raw materials is more than 25%, the raw materials should be dried by rotary drum drying machine with a certain degree of humidity and particle size, as the moisture should be less than 25%.

5. Granulating: Use new type organic fertilizer pellet mill to granulate the raw materials into pellets, which can protect the microbial flora and the survival rate is more than 90%. Adjust the hole diameters of dies according the materials to achieve the optimal pelletizing results.

6. Drying: In the production of organic fertilizer, the pellets need to be dried at low temperature as the moisture is about 15%-20% and generally exceeding targets.

7. Cooling: The dried products enter into the cooling machine through a belt conveyor. The cooling machine uses cool gas to cool hot products and make full use of the exhaust heat.

8. Screening: we provide high-quality and good-performance rotary drum screening machine which is used for separating the returned materials and the finished products. The returned materials will go back to fertilizer crusher for further process, while the finished products are conveyed to fertilizer coating machine, or directly transported to automatic fertilizer packager.

9. Packaging: The finished products enter into the packing machine through the belt conveyor. The fertilizer packaging machine package finishes product quantitatively and automatically. Through creative thinking, more new technologies are added and applied in our packaging process, which makes the packager own both essential function and some specific properties which exactly satisfy the particular demands of different commodity and special environmental conditions.

Wide Application of New Type Fertilizer Production Line

1. Agricultural waste: straw, the dregs of beans, cotton dregs, rice bran, etc.

2. Animal manure: mixture of poultry litter and animal waste, such as the wastes of slaughterhouse, fish market, urine and dung of cattle, pigs, sheep, chicken, ducks, geese, goat, etc.

3. Industrial waste: wine lees, vinegar residue, manioc waste, sugar scam, furfural residue, etc.

4. Home scrap: food waste, the roots and leaves of vegetables, etc.

5. Sludge: the sludge of the river, sewer, etc.

Technical Data of Large Scale Organic Fertilizer Plant

|

Product Item

|

Model

|

Motor Power

(kw) |

Prod Capacity

(t/h) |

Weight

(t) |

Inclination

|

Dimension

L x W x H(mm)

|

|

Semi-wet Material Crusher

|

ALCBSFS-40

|

22

|

1-2

|

960*560*850

|

||

|

Horizontal Mixer

|

ALCZYQ-QZ 400

|

20

|

2.35

|

Rotating dia:400

|

||

|

New Type Granulator

|

ALCYSL-80

|

45

|

2-4

|

|||

|

Polishing Machine

|

ALCPYS1000

|

11

|

2

|

3100*1020*1390

|

||

|

Rotary Drum Dryer

|

ALCZG15150

|

15

|

5-7

|

2-5

|

Shell L x inner dia:

15000*1500 |

|

|

Rotary Drum Cooler

|

ALCLQ12120

|

7.5

|

2-5

|

Shell L x inner dia:

12000*1200 |

||

|

Rotary Drum Screening Machine

|

ALCGS1.2×4.5

|

3.0

|

3-5

|

2.5

|

2-2.5

|

Shell L x dia:

4500*1200 |

Friendly Tips:

If you are a first-time investor, Allance Machinery recommend Small Scale Organic Fertilizer Plant