On July 14, 2016, a new compound fertilizer production line, was loaded to export to Zimbabwe.

Our customer, Meeko, wanted to start a new produce compound fertilizer plant. Due to clear requirements, he told us his planned production capacity and raw materials firstly.

| Production Line | 50,000 ton Compound Fertilizer Production Line |

| Production capacity |

6-8t/h

|

| Raw material | Rare earth, ammonia, ammonium sulfate, ammonium chloride, etc. |

| Target product | NPK, Phosphate fertilizers, MAP, DAP |

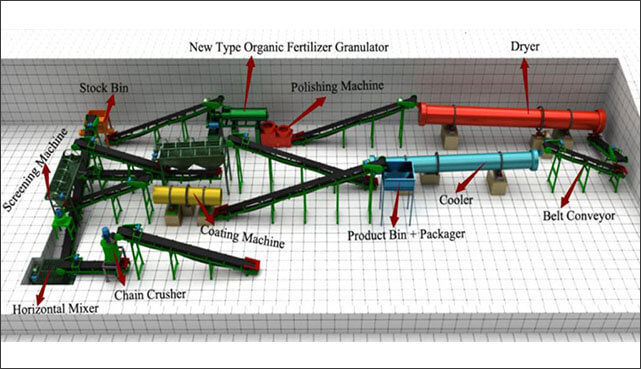

After knowing all his requirements, our technical designed a new compound fertilizer production line from raw material treatment to packaging. This fertilizer production line includes chain crusher—disc fertilizer mixer—rotary drum granulator—rotary drum dryer—rotary drum cooler—rotary drum screening machine—rotary drum coating machine—belt conveyor.

|

|

FAQs:

1. What is main raw materials for compound fertilizer production?

Compound fertilizer is a fertilizer that contains two and more essential plant nutrients. Compound fertilizer is divided into chemical compound fertilizer and mixed compound fertilizer. The common compound fertilizer is as follows:

|

Types

|

Main ingredients

|

Active ingredient

|

Application

|

|

MAP

|

NH4H2PO4

|

(N-P2O5-K2O)12-60-0

|

Used for all plants as base fertilizer and seed fertilizer |

|

DAP

|

(NH4)2HPO4

|

(N-P2O5-K2O)21-53-0

|

Used for all crops

|

|

KDP

|

KH2PO4

|

(N-P2O5-K2O)0-24-27

|

Used for top dressing

|

Compound fertilizer is in form of granules. Because of different production technology, the colors are different. The main raw materials are ammonium sulfate, ammonium nitrate, ammonium carbonate, ammonium chloride, urea, potassium sulfate, potassium chloride, ammonium phosphate, etc.

2. How to make the production line smoothly running?

In order to ensure normal running of the machines, technical should keep the routine maintenance. In this way, the machines, like chain fertilizer crusher and rotary drum fertilizer granulator, can be running normally.

3. What is temperature problem in compound fertilizer granulation?

In the process of granulation, granulation temperature is high, and then liquid phase system will be increased. The solubility of the inorganic salt increases gradually, with increasing mutual dissolution and reaction of the complex salt. Therefore, the degree of uniformity increases and the amount of the liquid phase should be appropriate. For example, as for urea and ammonium phosphate granulation, when temperature is adjusted from 60 degrees to 90 degrees, the moisture content of the material should be 3.2% down to 1.2%. In addition, the liquid phase viscosity and surface tension is reduced, resulting in particles with greater strength under mechanical force.

4. What is solubility problem for compound fertilizer raw materials?

As for high nitrogen compound fertilizer, the amount of urea is more than 50%. Due to the large solubility, the amount of liquid phase is high. It can be improved by the addition of powdered urea at lower operating temperatures. Urea dissolved endothermic makes granulation temperature reduced, increasing the difficulty of the operation. In addition, the low-melting mixture generated makes it is more difficult for granulation control.

5. How to adjust PH in compound fertilizer production?

It is an important indicator for material system. In ammonium phosphate granulation system, value control, between 6.0-6.5, is appropriate. When the material is acidic, it has high solubility. Violent reaction is prone to bond into a ball with cohesive property. Alkaline pH leads to large ammonia loss and poor reactivity. Thus, the material is not easy to diverge into pellets. You can add ammonium bicarbonate, calcium magnesium phosphate to adjust pH value. You can add small amount of adjustment facility ammonia gas and steam mixture into the granulated material layer to neutralize MAP. The heat of reaction can increase granulation temperature.

6. What is return material problems?

It has an impact on the granulation temperature and humidity. It is essential for granulation to strictly control some factors, such as the temperature of returning materials, particle size distribution and humidity of the granulation, etc.

7. What is effect of melting point of materials for viscosity?

The melting point of mixed materials is lower than the lowest melting point of the components. Eutectic point system of urea, potassium chloride and monoammonium phosphate is about 115 degrees. The temperature is the sticky point temperature. Granular operating temperature should be kept in this temperature. With water content increasing, urea-based compound fertilizer viscosity temperature decreases. Therefore, high temperature but low water conditions will not improve the granulation conditions. What’s more, it is bad for drying and screening process.

8. What are influencing factors for compound fertilizer production?

When the difference of granulation temperature and humidity is smaller than the condition in air, it is important to adjust to external environment. The operation of fertilizer granulator machine depends on the temperature of the granulation and humidity. The granulation temperature should be controlled between viscosity temperature and ambient temperature to maintain the proper temperature. In this way, the materials are not excessive viscous and have certain crystallization rate. You can reduce granulator outlet temperature and humidity of materials or the use two low-temperature drying machines. Although the cost is increased, it is reasonable for chemical fertilizer production.