The Liquid Organic Fertilizer Tank-Spreader Working Principle

The Liquid Organic Fertilizer Tank-Spreader is powered by a tractor, and the spraying hoses are arranged side by side to form a spraying support in the shape of a comb (sub-loose fertilization plowshare can also be configured). The liquid fertilizer stored in the tank is directly transported to the soil by a vacuum pump. An efficient new type of agricultural machinery equipment. The fertilization tanker has the characteristics of uniform delivery, reducing fertilizer evaporation, retaining fertility, and avoiding soiling crops.

Advantages of The Liquid Organic Fertilizer Tank-Spreader

1. The main components are all imported from Italy (including vacuum pumps, brass valves, pipe fittings, multi-way valves)

2. Axle: Adil in Italy or Monteluco in France, both adopt double axle and double tire structure, with hydraulic brakes.

3. The body is made of high-strength carbon steel

4. Anti-corrosion: hot-dip galvanizing process is used both inside and outside the tank

5. The whole machine adopts self-priming and spraying integrated design.

International PTO shaft with high reliable quality on the machine , which makes sure the power supply correctly.

Italy imported vacuum pump to ensure a perfect performance.

Italy ADR axle with good braking, accurate and sensitive automatic steering system, it’s safe and durable.

Whole tank with hot dip galvanizing processing to prevent corrosion.

Advanced hydraulic auxiliary system to provide power to operate.

Air filter to avoid impurities into the pump

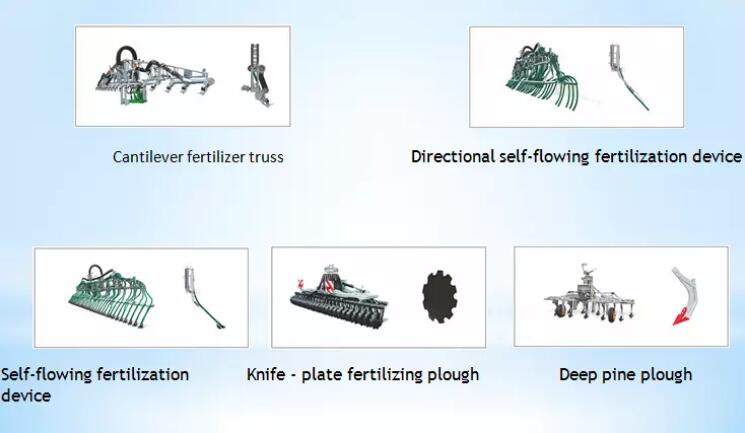

Optional Fertilizing Device For The Tank-Spreader

Optional fertilization device: cantilever spraying fertilization truss, comb blade type fertilization device, gravity fertilization truss, disc harrow type fertilization plowshare, injection submerged fertilization plowshare (as shown below)

The Fertilizer Tank-Spreader Technical Parameter

| Model | Weight | Total Length | Operation mode | Tank diameter | Tank volume | Supporting power |

| SF12000 | 5100kg | 8150mm | Hydraulic | 1800mm | 12000L | 150-220HP |

| SF16000 | 6500kg | 8500mm | Hydraulic | 2000mm | 16000L | 160-240HP |

| SF20000 | 7500kg | 9800mm | Hydraulic | 2000mm | 20000L | 170-250HP |

| SF24000 | 8500kg | 10000mm | Hydraulic | 2100mm | 24000L | 180-260HP |

| SF28000 | 9500kg | 11500mm | Hydraulic | 2100mm | 28000L | 190-280HP |

| SF32000 | 12000kg | 11500mm | Hydraulic | 2300mm | 32000L | 200-300HP |